3D Printed Trophies

& Awards

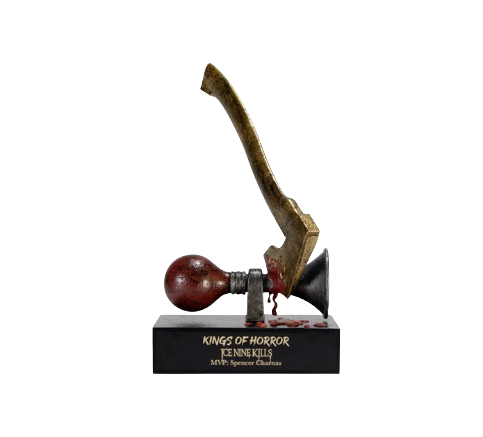

Innovation meets recognition. Cutting-edge 3D printing technology creates impossible geometries and limitless design possibilities for truly unique recognition solutions.

Custom 3D Printed Trophy Designs

Our 3D Printed Trophy

Capabilities

3D printed awards represent the frontier of recognition innovation, enabling complex designs and rapid prototyping that traditional manufacturing methods simply cannot achieve.

-

Create intricate geometries, internal structures, and interconnected elements impossible through traditional casting or fabrication methods

-

Test and refine designs quickly with physical samples before committing to final production runs

-

Produce limited quantities or unique variations without expensive tooling or mold creation

-

Advanced materials provide structural integrity while maintaining manageable weight for display and shipping

-

Achieve flowing curves, lattice structures, and complex architectural elements with precision accuracy

-

Modify designs between production batches without retooling, perfect for evolving recognition programs

Clients We’ve Worked With

What Customers Say About Our 3D Printed Trophies

“We really enjoyed working with Bennett Awards. Our design was non-standard and they worked with us to make it a reality: a 3D M cut in half along the vanishing point to symbolize a half marathon. Throughout the process, as our project gained internal momentum as the First Annual Facebook Half Marathon, they worked with us to create a second design – a medal for 12 of the winners – that matched the main trophy. It was so beautiful we had it on display at the finish line and received many compliments from Facebook employees and designers. This is no easy audience to impress and we made an impression. On time, responsive, and true to imagined form – thanks, we will be using them again! ”

Jared Morgenstern, Facebook Inc.

Case Study

Arbys “Race for the Cheesesteak” Tro

When Arby's and The Tombras Group wanted to transform the 2025 NASCAR Chicago Street Race into an unforgettable promotional moment for their new Angus Cheesesteak sandwich, they faced a unique challenge: create a trophy that could literally hold the sandwich while making a bold statement on national television.

3D printed awards from Bennett combine technological innovation with design expertise, creating recognition pieces that showcase your commitment to forward-thinking excellence. Whether you need impossible geometries, rapid turnaround, or cost-effective customization for multiple variants, additive manufacturing delivers solutions traditional methods cannot match.

Ready to Push

Design Boundaries?

FAQs for 3D Printed Awards

-

Bennett Awards creates 3D printed custom awards using engineering-grade polymers, composite materials, and specialty filaments delivering excellent surface finish, dimensional stability, and long-term durability. Our industrial additive manufacturing systems produce awards with precision layer resolution and consistent material properties. Post-processing techniques including sanding, coating, and finishing transform printed pieces into refined recognition with premium aesthetics.

-

3D printed custom trophies enable unlimited design complexity including intricate lattice work, impossible geometries, organic flowing forms, internal voids and structures, complex assemblies as single pieces, topology-optimized shapes, and architectural elements impossible through traditional casting or fabrication. This design freedom allows innovation-focused organizations to create recognition pieces literally impossible to manufacture through conventional methods.

-

Custom 3D printed awards typically require 2-4 weeks depending on design complexity, size, quantity, and finishing requirements. 3D printing enables rapid prototyping with physical samples produced in days for design approval before final production. This speed advantage makes additive manufacturing ideal for tight deadlines, iterative design processes, or recognition programs requiring quick turnaround without expensive tooling or mold creation.

-

Yes. 3D printing's digital manufacturing enables cost-effective customization for individual recipients including personalized names, unique achievement details, varied colors, or design modifications without tooling changes. This mass-customization capability suits recognition programs where each recipient deserves personalized awards rather than identical pieces—delivering meaningful individualization impossible or cost-prohibitive through traditional manufacturing.For every custom project, we start by listening: to your goals, your timeline, your brand story. Then we recommend the most effective production path to bring that vision to life—without bias, without limits. Our versatility is your competitive edge, and your success is our priority.

-

Modern 3D printed custom awards using engineering-grade materials provide excellent durability for display applications. While not matching centuries-long bronze longevity, quality 3D prints resist breaking, maintain dimensional stability, and hold colors through decades of normal display. Post-processing coatings enhance surface durability and UV resistance. For recognition displaying in offices or homes, 3D printed awards deliver entirely appropriate longevity.

-

3D printed custom trophies accept diverse finishing treatments including sanding for smooth surfaces, priming and painting for color integration, metallic coatings creating metal-like appearance, clear coatings for protection and sheen, polishing for glossy finishes, and texture applications. These post-processing techniques transform visible print layers into refined surfaces indistinguishable from traditionally manufactured recognition pieces.