Inside the Custom Award Design Process: From Concept to Creation

The room quiets. A name is read. Applause swells. At that moment, an award is lifted from the stage lights and placed into someone’s hands. Its weight feels deliberate. Its form feels intentional. It carries more than a logo or a date; it carries meaning.

What most people see is the final artifact. What they rarely see is the journey that brought it there: the custom award design process that transforms abstract ideas into tangible recognition.

At Bennett Awards, every custom award begins long before materials are cut or metal is cast. Understanding how custom awards are made requires looking beyond manufacturing alone. It begins with a story, a purpose, and a blank page. From early discovery conversations to final finishing and delivery, each award design step builds on the last, transforming vision into physical form through a carefully guided collaboration between client and studio.

This is the anatomy of custom trophy creation; not as a product pulled from a catalog, but as a piece of art created with intention, craftsmanship, and respect for the achievement it represents. This is bespoke award manufacturing at its finest.

Discovery: Understanding the Story

Before a single sketch is drawn, the most important work in the custom award design process happens through conversation. Discovery is where meaning is defined and the foundation for the entire handcrafted award process is established.

Our designers begin by learning why the award exists. Is it honoring innovation, leadership, endurance, or cultural impact? Who will receive it, and how should it make them feel when they hold it? What values does the organization want reflected through form, material, and scale? These questions shape every subsequent award design step.

This phase often explores brand identity elements such as typography, color systems, architectural references, or historical motifs. For some clients, the inspiration is deeply symbolic. For others, it is rooted in performance, speed, legacy, or community. No two stories are the same, which is why no two custom awards should be either.

Discovery also establishes practical considerations in custom trophy creation. Quantity, timeline, presentation environment, and budget all inform the creative direction. Rather than limiting creativity, these constraints help shape smarter design decisions later in the process.

Example: Kelce Brothers’ Golden Baby Award

The Golden Baby Award began with a story that was equal parts humor, fandom, and legacy. NFL stars Jason and Travis Kelce approached Bennett Awards after a chance social media discovery, seeking a trophy that would resonate deeply with the audience of their podcast, New Heights. Early discovery conversations revealed inspiration drawn from iconic sports trophies like the Stanley Cup and the NFL Trophy, paired with a personal anecdote from Jason Kelce’s early career. That narrative foundation guided every creative decision that followed, ensuring the final piece felt both monumental and unmistakably personal.

By the end of discovery, the design team has a clear creative brief. This becomes the foundation for every award design step that follows, ensuring the final award is not just visually striking, but purpose-built for the moment it represents.

Sketching and Concept Exploration

With the story defined, ideas begin to take shape on paper. This is where the custom award design process moves from abstract conversation to visual possibility.

Sketching is where exploration happens quickly and freely. Designers develop multiple thumbnail concepts, testing different silhouettes, proportions, and symbolic directions. Some sketches may lean architectural and bold, while others explore organic or sculptural forms. At this stage in how custom awards are made, variety matters more than polish.

Clients are often surprised by how many directions are explored early on. This breadth allows meaningful conversation and refinement. Together, we discuss what resonates, what feels aligned with the story, and what can be pushed further. This collaborative approach is essential to bespoke award manufacturing. The client’s vision shapes the outcome at every stage.

Sketches are not about perfection. They are about possibility. They invite collaboration and allow clients to see how abstract values, such as leadership, innovation, endurance, can begin to translate into physical form. Through feedback and iteration, one or two concepts emerge as the strongest expressions of the award’s purpose.

These selected concepts move forward as the blueprint for the next phase of custom trophy creation, where ideas begin to gain dimensionality and precision. This iterative process ensures that the final design is not only beautiful but deeply connected to the story and values it represents.

The handcrafted award process relies on this balance between artistic exploration and strategic refinement. By presenting multiple directions early, we ensure that the chosen concept has been tested against alternatives and truly represents the best solution for the recognition moment ahead.

3D Modeling and Design Refinement

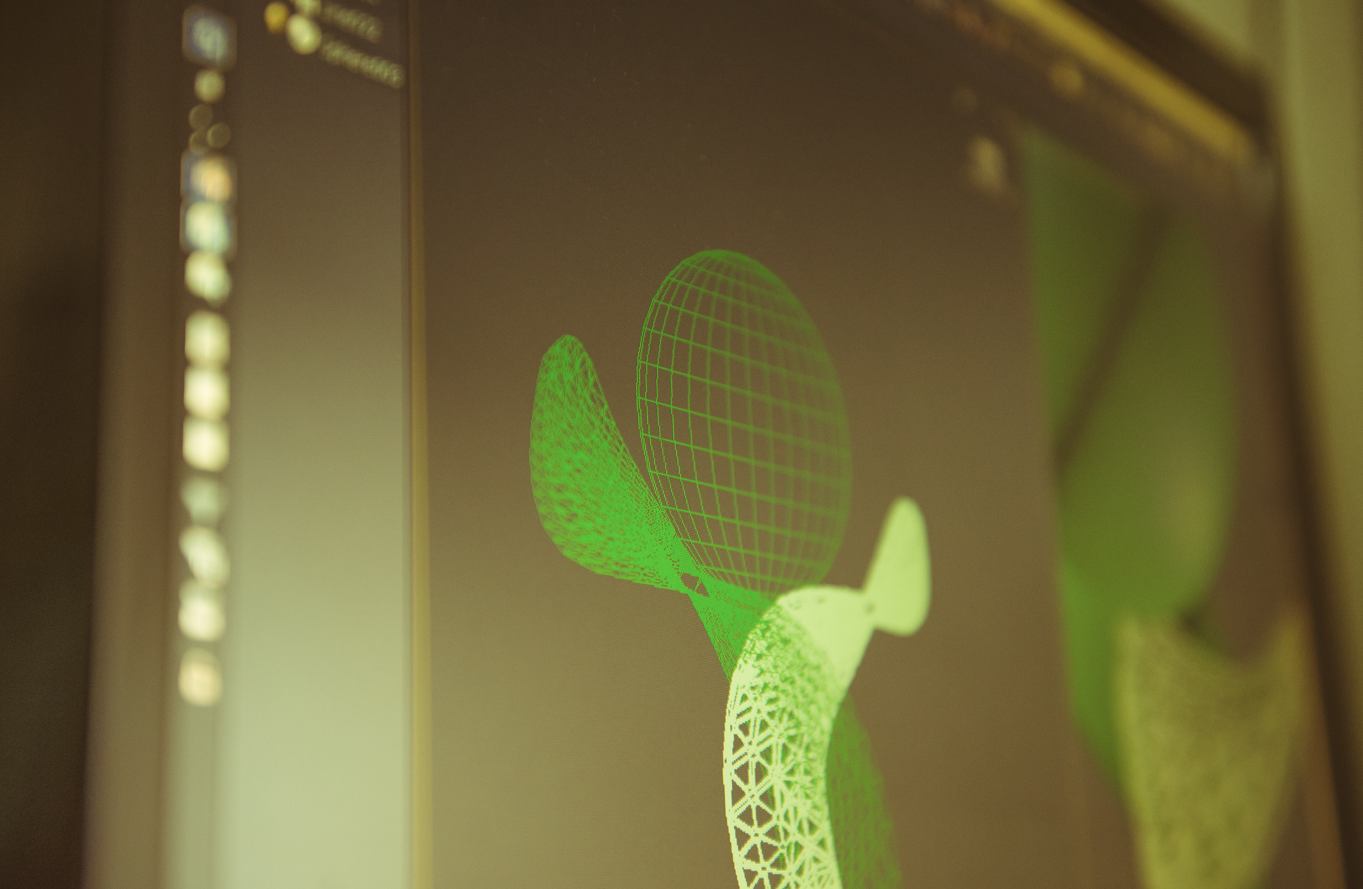

Once a concept is approved, the award design step transitions from paper into digital space. This is where the custom award design process gains precision and three-dimensional reality.

Using advanced 3D modeling and digital sculpting tools, designers refine the form in full scale. Proportions are adjusted, edges softened or sharpened, and structural elements engineered for stability and longevity. This phase is critical in understanding how custom awards are made with both artistic intent and structural integrity.

Engraving areas, logo placement, and text hierarchy are carefully integrated into the design rather than treated as afterthoughts. Every detail is considered, from how light will interact with curved surfaces to how the award will rest on a shelf or in a display case. These considerations distinguish bespoke award manufacturing from mass production.

This stage in custom trophy creation allows clients to visualize the award from every angle. High-quality renderings show how light interacts with surfaces and how materials might behave in real-world conditions. Changes can be made efficiently, ensuring alignment before physical production begins. This digital refinement stage saves time and resources while maintaining creative flexibility.

3D modeling also plays a critical technical role. It ensures that the design can be fabricated accurately using the chosen manufacturing methods, whether that involves casting, machining, or mixed-media assembly. The model serves as a blueprint for every craftsperson involved in the handcrafted award process.

By the end of this phase, the award design is finalized digitally, balancing artistic intent with structural integrity and manufacturability. Every dimension, every curve, and every detail has been refined to ensure the final piece will be both beautiful and built to last. This meticulous attention to digital precision is what separates truly custom work from modified templates.

Material Selection and Structural Planning

Materials are never chosen for appearance alone in the custom award design process. They carry meaning, weight, and permanence. Understanding how custom awards are made requires recognizing that material choice is both aesthetic and symbolic.

During material selection, designers consider how different materials reinforce the story behind the award. Metal may communicate endurance and prestige. Crystal can suggest clarity or excellence. Wood introduces warmth and craftsmanship. Mixed materials often create contrast and depth, elevating the final piece. Each choice is deliberate in custom trophy creation.

Structural planning happens alongside aesthetic decisions in bespoke award manufacturing. The weight of the award, its center of gravity, and how components are joined all matter. An award should feel substantial in hand, balanced on a surface, and durable enough to last for generations. This is where engineering meets artistry in the handcrafted award process.

Finish options are also explored here, from polished and brushed metals to patinas, anodizing, or powder coating. Each finish changes how light and texture interact with the form, affecting both visual impact and tactile experience.

Example: ACLU Bill of Rights Awards

For the ACLU of Southern California’s Bill of Rights Awards, material choice was inseparable from meaning. The awards honor individuals who challenge the status quo in pursuit of inclusion and belonging. Bennett Awards designed a torch-inspired form, symbolizing vigilance and progress, machined from aluminum and finished with a bead-blasted, nickel-plated surface. Standing 11 inches tall, the material and finish choices balanced strength, restraint, and dignity, reinforcing the gravity of the mission behind the recognition.

By aligning material choice with symbolism and engineering, the award becomes not just visually compelling, but physically meaningful. This alignment is a hallmark of the custom award design process and distinguishes true bespoke work.

Prototyping and Scale Models

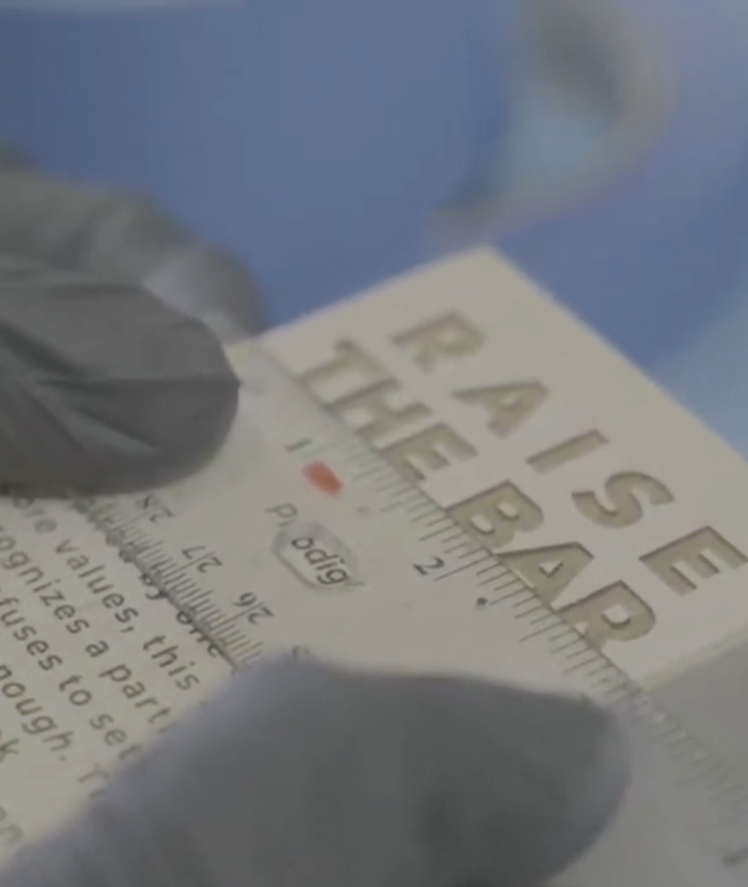

Before full production begins in custom trophy creation, ideas are tested in the physical world. Prototyping is a critical award design step that reveals insights digital models cannot fully capture.

Prototyping allows designers and clients to evaluate scale, proportion, and tactile experience. Depending on the design, this may involve resin models, 3D printed components, or hand-finished maquettes. These prototypes reveal details that digital models cannot fully capture in the custom award design process, such as how an edge feels in hand or how light reflects off a curved surface.

This phase in how custom awards are made often leads to subtle refinements. A base may be adjusted for stability. A curve may be softened. An engraving area may be enlarged for legibility. These adjustments ensure the final piece performs as beautifully as it appears.

Example: Google Retail Performance Awards

Prototyping played a critical role in refining Google’s Retail Performance Awards. The design featured a circular puck form made from manufactured maple wood, with an integrated plexiglass Google “G” logo illuminated by internal LED lighting. Physical prototypes ensured the lighting diffusion, balance, and edge-standing capability functioned seamlessly, while also confirming that laser-etched personalization remained legible without disrupting the minimalist form.

Prototyping ensures confidence before fabrication begins in bespoke award manufacturing. It is a checkpoint where form, function, and meaning are confirmed in three dimensions. This step in the handcrafted award process prevents costly revisions and ensures the final piece meets expectations.

Fabrication: Sculpting, Casting, Machining, and Assembly

Fabrication is where the custom award design process truly comes to life. This is where digital precision meets human craftsmanship in the most tangible expression of how custom awards are made.

Inside the workshop, skilled artisans translate the approved design into finished components. Depending on the project, this may involve traditional sculpting, metal casting, CNC machining, or a combination of techniques. Each method is selected based on the design’s needs and material requirements. This flexibility is essential to bespoke award manufacturing.

Cast components are refined by hand, with artisans carefully removing seams, smoothing surfaces, and perfecting contours. Machined parts are inspected for precision, ensuring every dimension matches the digital model. Surfaces are sanded, polished, or textured to achieve the desired finish. This is the heart of the handcrafted award process.

Engravings are executed with accuracy and care, ensuring names and details are as permanent as the achievement itself. Whether laser-etched, mechanically engraved, or hand-tooled, personalization is integrated seamlessly into the design.

Assembly brings all elements together in custom trophy creation. Mixed materials are aligned, bonded, or mechanically joined. Every piece is handled multiple times by craftspeople who understand the importance of consistency and detail. This stage requires both technical skill and artistic judgment.

Example: The Harvey Awards

For the Harvey Awards, one of the comic industry’s most prestigious honors, fabrication centered on honoring legacy. Bennett Awards worked closely with event organizers to create a new family of awards featuring a sculptural likeness of the awards’ namesake, Harvey Kurtzman. Each sculpture was hand-sculpted by Bennett artist James Shoemaker, cast in resin, and finished in either dark bronze or gold for the distinguished Golden Harvey. Mounted on circular marble bases, these awards reflect both artistic craftsmanship and deep respect for Kurtzman’s enduring influence on comics and culture.

This stage is labor-intensive and deeply human. It is where craftsmanship defines quality and where the custom award design process transforms from concept to physical reality. Every hand that touches the piece contributes to its final character.

Finishing Touches and Delivery

The final award design step is about refinement and respect. This is where the custom trophy creation process reaches completion, ensuring every detail meets the standard set from the beginning.

Finished awards undergo quality control inspections to ensure consistency across the full run. Edges are checked, finishes reviewed, and engravings verified. This attention to detail is what separates bespoke award manufacturing from volume production.

Packaging is designed to protect the award in transit and present it with care upon arrival. Whether shipping a single custom trophy or hundreds of awards for a global event, logistics are handled with precision in the handcrafted award process. Timing matters, and delivery is planned to support rehearsals, presentations, and event schedules.

Example: Andersen Chairman’s Awards

For Andersen Corporation’s Chairman’s Awards, finishing details reinforced the prestige of the recognition. The layered awards were crafted from Ponderosa Pine with naturally occurring blue stain, accented by a recessed metal band. Vertical and horizontal engravings highlighted award titles, core values, and the Andersen logotype. Careful finishing and inspection ensured each award conveyed consistency, craftsmanship, and respect for the achievements being honored.

When the award arrives, it is ready for its moment. This is the culmination of the custom award design process: a journey from story to physical form, guided by collaboration, craftsmanship, and intention.

Bring Your Vision to Life with a Custom Award

Every recognition moment deserves an award designed with intention. Understanding the custom award design process is the first step toward creating something truly meaningful: an award that honors achievement with the same care and commitment that earned the recognition in the first place.

At Bennett Awards, we guide clients through every award design step, from initial discovery to final delivery. Our team of designers and craftspeople specializes in bespoke award manufacturing and custom trophy creation that reflects your story, values, and vision. This is how custom awards are made when quality, symbolism, and craftsmanship matter.

Whether you’re honoring leadership, innovation, service, or achievement, we’re here to help you create an award that will be valued for generations. Our handcrafted award process ensures every detail is considered, every material is purposeful, and every piece is built to last.

Ready to begin? Let’s sketch the first draft of your story. Contact Bennett Awards today to start your custom award design process.