Machined Metal

Awards & Trophies

Precision engineering meets contemporary design. High-polish aluminum, steel, and specialty alloys transformed into enduring recognition through precision manufacturing.

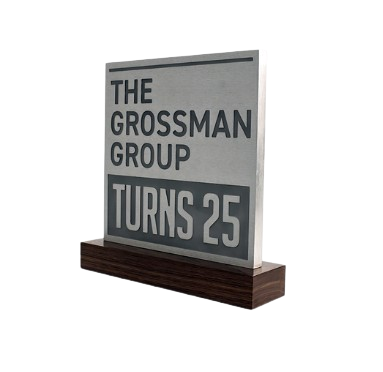

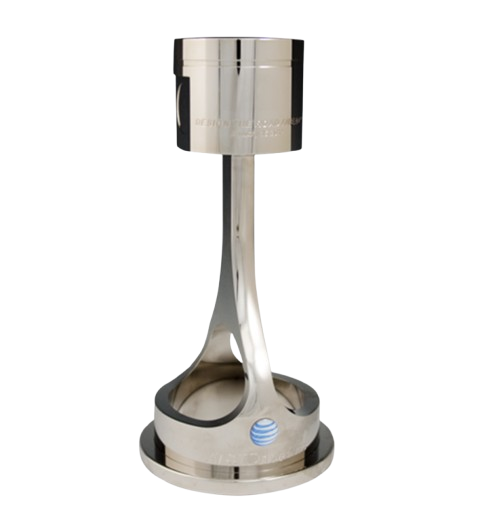

Machined Metal Award Designs

Our Machined Metal Capabilities

Machined metal awards combine engineering precision with contemporary aesthetics, creating recognition pieces that communicate innovation, quality, and attention to detail.

Bennett Awards utilizes advanced CNC machining and precision fabrication to transform aluminum, stainless steel, and specialty alloys into awards with flawless finishes and exacting dimensional accuracy.

-

Computer-controlled machining delivers tolerances measured in thousandths of an inch, ensuring perfect consistency across production runs. This precision enables complex geometric forms, clean edges, and uniform dimensions that hand-fabrication cannot achieve—ideal for logos, architectural forms, and contemporary designs requiring exactitude.

-

Aluminum provides lightweight strength with excellent machinability for intricate details. Stainless steel delivers superior corrosion resistance and substantial feel with mirror-like polish potential. Specialty alloys offer unique colors, weights, and properties serving specific design requirements. Each material accepts diverse finishing treatments enhancing visual impact.

-

Machined metals accept extensive finishing treatments transforming raw material into refined recognition. Options include mirror polishing, brushed finishes, anodizing (adding color to aluminum), powder coating, plating, and specialty treatments creating unique surface textures. These finishes protect metals while enhancing aesthetic appeal and brand alignment.

-

Machining excels at creating precise geometric forms—clean angles, perfect circles, uniform thicknesses—that communicate professionalism and quality. This geometric precision particularly suits technology companies, engineering firms, and organizations where precision represents core values worth emphasizing through recognition design.

-

Machined metal awards naturally align with modern design sensibilities. Clean lines, reflective surfaces, and architectural forms create recognition feeling current and forward-thinking—ideal for brands positioning themselves as innovative, contemporary, or design-forward.

-

Unlike handcrafted processes that introduce natural variations, machining delivers identical pieces regardless of quantity. This consistency ensures every recipient receives recognition indistinguishable from others—important for programs where fairness and equality matter.

Options for Machined Metal Awards

Multiple Sizes

As stated above, custom fabricated metal awards can be created in nearly any size, ranging from a small medallion to large, freestanding awards that can be mounted on a large stand and displayed in a lobby. Because there are no molds involved in the fabrication process, resizing an award is a relatively painless task, often saving money in the long run.

A Different Look

Fabricated metal awards often have an 'industrial' or 'modern' look. Due to the fabrication process, the end result yields custom awards with a sharper-edged or 'machined' look, which works better than sculpture awards in some situations that require this design aesthetic. A number of process-specific finishing options are also available when choosing fabricated metal Awards. A few of those processes are outlined below.

Custom Colors

Fabricated metal awards can be created in an endless variety and combination of colors. We utilize a number of processes to add color to your fabricated metal awards, including anodizing, powder-coating, painting, electroplating and several others. Outlined below are some of the most common finishes for fabricated metal awards. Be sure to talk with our knowledgeable sales team to find the best fit and finish for your project.

Anodizing

Anodizing is a quick and simple way to add a touch of color to a fabricated metal award. Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. The finish quality of the color is dependent on the finish of the metal. A high polished metal will produce a glossy look, while a brushed metal will produce a duller, flatter finish. Anodizing is perfect for adding color to an award while still keeping the raw material features (metal grain) intact. Anodizing is best utilized when applying one color to a large area. While anodizing is one of the least expensive options for adding color to an award, it is limited in the variety of colors you may choose, making some unusual brand color schemes tough to match.

Powder-Coating

Powder-coating is a type of coating that is applied as a free-flowing powder, not a liquid like paint, making it much easier to apply color to areas that traditional painting cannot reach. Powder-coating is by far the most durable of all the color finishes and was specifically created for such a purpose. This finish is best for covering large areas with a single color. This premium finish will hold up to the elements and works perfectly for both indoor and outdoor applications. Like anodizing, powder-coating finishes have a limited palette, so matching a custom branding color may prove difficult. But, unlike anodizing, there are literally hundreds of colors to choose from.

Painting

Painting is easily the most versatile of all of the finishing options for fabricated metal awards. Our fabrication team can create, mix, and match nearly any color or finish that your project may require. We work with many different types of paint, ranging from high quality automotive finishes, to epoxy resins, all the way down to a less expensive acrylic or enamel based paint. Paint can be finished in a number of different finishes as well, including high-gloss clear finishes, colored "candy apple" finishes, and matte flat finishes. The options are nearly endless. Just be sure to talk with a member of our sales team to find the right fit for your project.

Metal Plating

Much like our other awards, metal plating your fabricated metal awards is also an option. Metal plating has a very limited palette, however. We mostly work with the industry standard gold, silver, and copper plating. For a more detailed description, please see our Plating Options page.

Raw Metal Finishing

Another finish option when choosing fabricated metal awards, is to leave the metal, well, metal. We can opt to high polish the surface to give it a mirror-like appearance, or bead blast it to dull the surface (like most Apple products). We can provide a custom brushed finish, a scored finish, or even a custom grind finish to achieve the look you're after. As always, if you have any questions about raw metal finishes, consult a member of our sales team and they will answer any questions you may have.

Case Study

ACLU Bill of Rights Awards

Bennett collaborated with the ACLU to translate the themes of justice, equality, and advocacy into a sculptural form that embodies courage, leadership, and lasting significance.

Machined metal awards from Bennett combine precision engineering with contemporary design, creating recognition that communicates quality, innovation, and attention to detail.

Whether featuring corporate logos or geometric sculptures, our machined awards deliver flawless execution and modern sophistication.

FAQs for Machined Metal Awards

-

Bennett Awards creates machined metal awards using aluminum (lightweight with excellent machinability), stainless steel (superior corrosion resistance and substantial feel), brass (warm golden tones), and specialty alloys offering unique colors and properties. Each metal accepts diverse finishing treatments including mirror polishing, brushing, anodizing, powder coating, and plating for customized appearance matching brand aesthetics.

-

CNC (Computer Numerical Control) machining uses computer-controlled equipment delivering precision tolerances measured in thousandths of an inch. This precision manufacturing ensures perfect consistency across production runs, enables complex geometric forms with clean edges, and creates uniform dimensions impossible through hand-fabrication—ideal for corporate logos, architectural forms, and contemporary designs requiring exactitude and repeatability.

-

Yes. Machined metal custom awards excel at reproducing corporate logos with perfect dimensional accuracy. CNC technology translates vector artwork into three-dimensional metal forms maintaining precise brand specifications. Logos can be machined as standalone sculptures, integrated into larger award designs, or featured as prominent elements on plaques and bases—ensuring flawless brand representation in recognition pieces.

-

Machined metal custom trophies accept extensive finishing treatments including mirror polishing (reflective surfaces), brushed finishes (contemporary matte appearance), anodizing for aluminum (adding color through electrochemical process), powder coating (durable color application), electroplating (chrome, gold, or nickel surfaces), and specialty textures. These finishes protect metals while enhancing visual impact and supporting brand color matching.

-

Machined metal awards use subtractive manufacturing (removing material from solid blocks) while cast awards use additive processes (pouring molten metal into molds). Machining delivers geometric precision, contemporary aesthetics, perfect consistency across quantities, and typically shorter lead times. Casting enables organic sculptural forms, intricate relief details, and traditional fine art appearance. Material choice depends on desired aesthetic and design requirements.

-

Machined aluminum custom awards deliver contemporary prestige through precision engineering, flawless finishes, and modern aesthetics—qualities highly valued by technology companies, innovative brands, and design-forward organizations. While bronze conveys traditional fine art heritage, aluminum represents cutting-edge manufacturing and contemporary sophistication. Prestige derives from design excellence and craftsmanship quality regardless of specific metal selection.

-

Technology companies, engineering firms, automotive manufacturers, architectural practices, and innovation-focused organizations frequently prefer machined metal custom awards because precision manufacturing aligns with their core values. The geometric accuracy, contemporary aesthetics, and engineering excellence inherent in machined awards resonate with industries where precision, innovation, and modern design represent fundamental brand attributes worth emphasizing through recognition.