Finish Options for Your Awards

One of the key advantages of working with Bennett Awards is the breadth of different types of award designs we can create. This variety helps us zero in a custom award design that is the best fit for your needs. This breadth applies not only to the materials we use, or the production processes we employ (see XXX), but also to the finishes we can use for each different type of award we create. Some of the finish options available for your awards are outlined below, followed by a glossary with a more detailed explanation and example swatch of each type of finish.

Primary Finish Options for Each Award Type

3D Printed Materials (Polymers, etc.)

Airbrushed

Painted (automotive paint)

Plated (very expensive)

Acrylic

Digital Printed

Laser Etched/Engraved

Aluminum

Anodized

Painted (automotive paint)

Bead Blasted

High Polished

Plated

Powder Coated

Sand Blasted

Satin Finish (brushed)

Note: Combo finishes are also possible (e.g., plated, then bead blasted), although most of these carry a premium price

Bronze

High Polished

Patinaed

Plated (gold/silver/nickel – rare; only as required)

UV Treated (exterior awards)

Crystal

Surface Engraved (color fill a premium option)

Sub-Surface Engraved

Digital Printed

Pewter

Satin Finish

Plated

Wood

Dyed (organic dye)

Lacquered (matte to gloss)

Painted

Sealed (hand-rubbed)

Stained

Unfinished

Glossary

Airbrushing

Airbrushing is a technique of applying paint or other media to a surface using an airbrush, which is a small, handheld device that sprays a fine mist of paint or ink. It allows for precise control and the ability to create smooth gradients, fine details, and various effects on a wide range of surfaces. Airbrushing is widely used in various artistic and creative fields, including illustration, automotive customizations, makeup and body art, model making, textiles, cake decorating, and more. Airbrushing is a versatile method to create detailed and intricate designs with smooth transitions and precise control over color application.

Anodizing

Anodizing is an electrochemical process used to coat or treat the surface of metals, primarily aluminum. It involves the formation of a controlled oxide layer on the metal's surface through the application of an electric current. Overall, anodizing offers a range of advantages, including corrosion resistance, durability, aesthetic versatility, improved hardness, electrical insulation, ease of maintenance, and eco-friendliness.

Automotive Painting

Automotive painting refers to the process of applying paint and other coatings to the surfaces of objects (usually metal). Automotive painting serves both functional and aesthetic purposes, providing protection against corrosion, weathering, and damage, as well as enhancing the visual appearance of the object. Automotive painting requires skill, precision, and the use of specialized equipment and materials to achieve high-quality results.

Bead Blasting

Bead blasting is a surface preparation technique used to clean, smooth, or texture the surface of a material by propelling small spherical particles, called beads, at high velocity onto the surface. The process can be adjusted to achieve different levels of surface roughness, ranging from a smooth satin finish to a rough texture for improved adhesion of coatings or paints. One of the advantages of bead blasting is its ability to achieve a uniform and consistent finish on complex shapes and hard-to-reach areas.

Digital Printing

Digital printing refers to the process of reproducing images or text directly from a digital file onto a variety of surfaces using a digital printing device. Unlike traditional printing methods, such as offset printing or screen printing, which require the creation of physical plates or screens, digital printing allows for direct printing from a digital source without the need for intermediate steps.

High Polishing

High polished metal refers to a surface finish on metal objects that has been polished to achieve a highly reflective and smooth appearance. The process involves removing imperfections, scratches, and any surface irregularities to create a mirror-like shine. The reflective and lustrous appearance of high polished metal adds a touch of elegance and sophistication to the finished product.

Laser Etching

Laser etching, also known as laser engraving or laser marking, is a process that uses a laser beam to create precise and permanent markings, designs, or patterns on a variety of materials. It involves removing or altering the surface material of an object by focusing a concentrated beam of laser light onto the surface. Laser etching offers several advantages over traditional etching methods, including heightened precision, the ability for finer details, application versatility, and permanence and durability.

Patination

Patination refers to the process of deliberately or naturally developing a thin layer of oxidation or other chemical alteration on the surface of a material, typically metal, to achieve an aged or weathered appearance. It is a controlled form of corrosion or chemical transformation that enhances the visual appeal and character of the object. It can enhance the aesthetic appeal of a piece, create an antique or vintage look, or provide a sense of authenticity and history. Patination is often valued for its unique and individualistic nature, as each patina develops uniquely based on the specific materials, environment, and techniques employed.

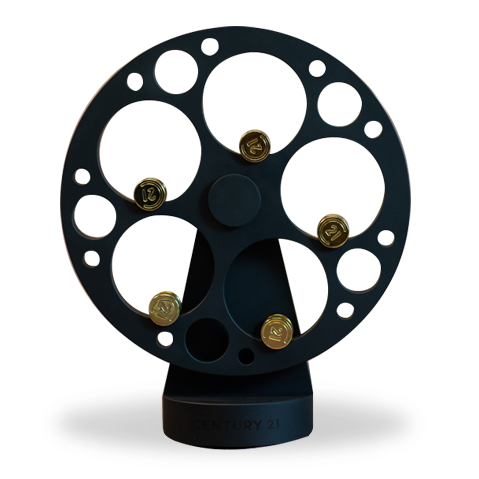

Award Example: Chevron Anchor

Plating

Plating, also known as electroplating, is a process in which a thin layer of metal is deposited onto the surface of an object, typically a base metal or substrate. The purpose of plating is to enhance the appearance, improve corrosion resistance, provide wear resistance, facilitate soldering or brazing, and offer other functional or decorative benefits.

Powder Coating

Powder coating is a finishing process commonly used to apply a durable and protective coating to the surface of various materials, particularly metals. It involves the application of dry, finely ground particles of pigment and resin, known as powder, onto the surface, which is then cured to form a solid, continuous coating. Powder coating offers several advantages over traditional liquid coatings. It provides a highly durable and resistant finish that is less prone to chipping, scratching, fading, or corrosion. The process is also more environmentally friendly as it does not involve the use of solvents and produces minimal waste.

Sand Blasting

Sandblasting, also known as abrasive blasting or media blasting, is a surface preparation technique used to clean, roughen, or etch the surface of a material by propelling fine particles of abrasive material at high velocity using compressed air or a blasting machine. The abrasive material, commonly sand but also including materials like glass beads, aluminum oxide, or garnet, is directed onto the surface to remove contaminants, coatings, or to create a textured finish. Sand blasting is an efficient method for surface preparation before painting, coating, or bonding processes. It can also be used to etch or engrave surfaces, create a matte or textured finish, or remove imperfections from materials like metal, concrete, wood, or glass.

Satin Finish

A satin finish refers to a surface texture or appearance that has a smooth and semi-glossy sheen. It is characterized by a subtle and soft reflection of light, creating a lustrous and elegant effect. A satin finish falls between a high-gloss finish and a matte finish in terms of reflectivity. Satin finishes are favored for their versatile and elegant appearance. They offer a compromise between the high reflectivity of glossy finishes and the flatness of matte finishes.

Subsurface Engraving

Subsurface engraving, also known as subsurface laser engraving or 3D laser engraving, is a technique used to create three-dimensional images or designs inside transparent materials, such as glass, crystal, acrylic, or certain types of plastics. Unlike traditional surface engraving, which creates marks or patterns on the surface of the material, subsurface engraving involves manipulating light and laser energy to create intricate internal structures within the material. Subsurface engraving combines the elegance of transparent materials with the precision of laser technology to create visually captivating and durable engravings.

Surface Engraving

Surface engraving on crystal refers to the process of creating designs, patterns, or text on the outer surface of a crystal object using engraving techniques. It involves removing material from the crystal's surface to form precise and detailed markings, resulting in a visually appealing and personalized decorative piece. Surface engraving on crystal objects allows for customization, personalization, and the addition of decorative elements. The engraved designs on the crystal surface catch and reflect light, resulting in an elegant and eye-catching display.

Unfinished Wood

Unfinished wood refers to wood that has not undergone any surface treatment or finishing. It has not been coated with paint, stain, varnish, lacquer, or any other protective or decorative finish. Unfinished wood retains its natural appearance, color, and texture. Unfinished wood appeals to those who appreciate the natural aesthetic of wood and prefer the ability to customize the appearance with their choice of finishes. Unfinished wood also provides a more tactile experience, as it retains the natural texture and feel of the wood.

UV Treatment

UV treatment, also known as UV resistant or UV stabilized, refers to a treatment or formulation designed to protect materials or products from the harmful effects of ultraviolet (UV) radiation. UV radiation is part of the electromagnetic spectrum emitted by the sun and can cause damage to various materials and surfaces over time. UV treatment offers several advantages, including fast processing times, no chemical residue or by-products, and effective destruction of microorganisms without the development of resistance. It is a versatile and environmentally friendly method for various applications that require sterilization, disinfection, or curing processes.

Wood Dying

The wood dyeing process involves applying dye or stain to wood surfaces to change or enhance their color. It is a method of coloring wood that allows the natural grain and texture of the wood to remain visible while altering its appearance.

Wood Lacquering

Wood lacquering is a finishing technique used to enhance and protect the surface of wood. Lacquer is a clear or colored coating that is applied to wood to create a durable and glossy finish. It provides a smooth and lustrous appearance while highlighting the natural beauty of the wood grain. The advantages of wood lacquering include protection, a smooth and glossy finish, and easier maintenance.

Wood Sealing

Wood sealing refers to the process of applying a protective coating or sealant to wood surfaces to prevent moisture penetration, enhance durability, and preserve the natural beauty of the wood. Sealing wood helps to reduce the risk of warping, cracking, rotting, and other forms of damage caused by exposure to moisture, UV rays, and environmental factors.

Wood Staining

Wood staining is a process of applying a colored pigment or dye to wood surfaces to alter or enhance their natural color while allowing the wood grain to remain visible. Stains are absorbed into the wood fibers, resulting in a semi-transparent or translucent finish that adds depth and character to the wood. Benefits of wood staining include color enhancement, grain enhancement, transparency, and application versatility across a variety of wood species.

Let’s Get Started!

This should give you an idea of the many options we have available for finishing your awards. These finish options help to customize the award and make it a perfect fit for your needs. We look forward to discussing your award project, and recommending the best approach - including finish options - for your requirements. We look forward to hearing from you!